As this procedure is performed without heat so no oxide is formed on the surface resulting in a smooth surface. Metal wire drawing plays a huge roll in the manufacturing industry in the.

The Science Backed Ways That Sketch Drawing Improves Mood

Drawing to Enhance Writing.

. Here a wire-shaped die is used. Large numbers of a given casting can be produced quickly. Another distinct advantage is the cost-effectiveness and speed of using a continuous process with permanent components.

The defect in this process can be easily detected and can be removed. It is a kind of extrusion process but not exactly. In commercial industry this process provides stock material for machining operations and for the manufacture of such items as fences coat hangers nails screws and bolts.

The advantages to using isometric pictorial is that it enables to sketcher to easily draw the objects they are sketching when it involves them being positioned in an angle. Advantages and Disadvantages of Metal Forming Process. The reasons for the success of the casting process are.

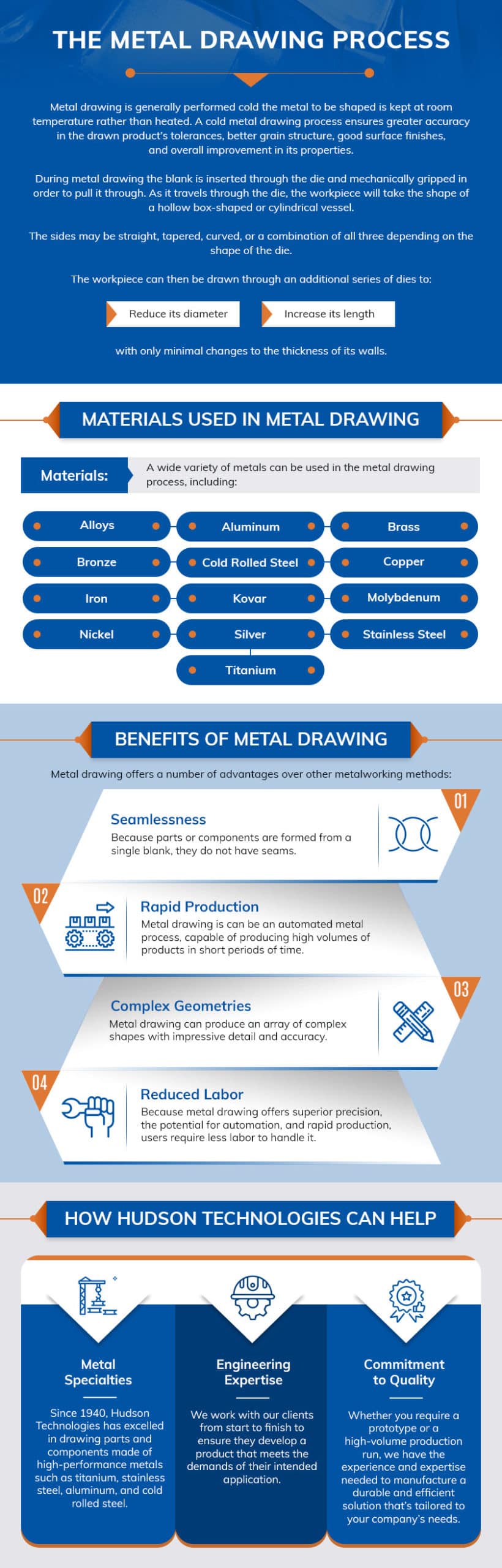

Benefit 1 Benefit 2 Benefit 3 Benefit 4 Deep drawn stamping is advantageous for use in production or projects requiring seamless elements rapid cycle times complicated axi-symmetric geometries as well as minimal labor. Rolling processes can be designed to produce workpieces with very close tolerances. Furthermore drawing can be applied both as a hot or cold process and is applicable to a wide range of materials and products.

This detail is based on Newell and Simons model the extensions of it to visual imagery by Kosslyn 10 11 12 and the effort to codify it by Anderson 13. Deep Drawing Advantages and Disadvantages 1. According to the above discussion you already have an idea that we can categorized forming process broadly in two types Hot Forming and Cold.

The method hardens the metal which yields finished components that are measurably stronger than machined or otherwise cast metal components. Process flowcharts have a variety of advantages that can bring tremendous value to your operation. Deep drawn stamping is advantageous for use in production or projects requiring seamless elements rapid cycle times complicated axi-symmetric geometries as well as minimal labor.

Complex cross-section profiles can be produced easily. The method hardens the metal which yields finished components that are measurably stronger than machined or. Studies have found that peoples moods improved after about 20 minutes of creative activity.

Skilled operators are not required. Owing to physical properties some metals can only be cast since they cannot be re-modelled into bars rods plates or other shapes. Limitations of rolling process.

Drawing is a metal forming process used to reduce cross section and increase length of work piece. Drawing can be a distraction from stress and other negative emotions and it can also serve to calm people. Sections are some advantages of the drawing process.

The major variables in drawing are similar to those in extrusion. Communication Process flowcharts are commonly utilized by industrial engineers and individuals involved with process improvement. When you are making designs you may find the need to make alterations.

High accuracy can obtain by this process. Doodling or coloring can put people into an almost meditative state calming and quieting their mind. Benefits aside one main disadvantage to the deep drawing process is that it isnt valued as effective in small quantities.

2 rows Deep drawing process has many advantages which include. It can use for mass product. Deep drawn stamping is advantageous for use in production or projects requiring seamless elements rapid cycle times.

The advantages of the rolling process is given as follows. Suitable for mass production. This process is mostly used for bulk production.

These advantages include the following. Process and Instrumentation Diagram The Process and Instrumentation Drawing or PID is also known as the mechanical flow diagram and piping and instrumentation diagram. A PID is a complex representation of the various units found in a plant.

In drawing the cross section of a round rod or wire is typically reduced or changed by pulling through a die. Hence it is known as Cold Forming Process. It also works well for sketching the depth width and height of an object easier with how the lines are angled on.

Reduction in cross-sectional area die angle friction along the die-workpiece interfaces and drawing speed. This process associated with tensile force which distinguishes it from other metal forming processes like extrusion forging etc. Advantages It is quick operation.

When you are using computer-aided design software it will be much easier to make any changes. The process is easy and does not require any skilled operator. It increases the strength and hardness of the metal but reduces the ductility.

No material wastage because it does not form any chips. It is a fast and less time consuming manufacturing process. Tensile compression forming is also suitable for small batch sizes and for individual production is flexible in terms of material thickness shapes and sizes has short reaction times causes only low tool costs allows the use of various materials permits efficient prototyping.

What are the advantages and disadvantages of deep drawing. When you are using the computer-aided design software it will save your time and you can make better and more efficient designs in shorter time duration. To discuss drawings role in the mechanical design process the characteristics of the STM the LTM and the information flow between them and the external environment will be developed.

Its a process highly adaptable to the requirements of mass production. It is used by people in a variety of crafts. The rapid cycle.

It requires less setup cost. It is simple process. Any material can be formed by this process.

One clear advantage of drawing is the simplicity of the components required to complete the process.

Metal Drawing How Metal Drawing Works

Why Drawing From Direct Observation Is Essential And 10 Tips To Improve Erika Lancaster Artist Content Creator Online Art Teacher

6 Benefits Of The Deep Drawing Forming Process Wiley Metal

Lecture 17 Drawing Practice And Force Ppt Video Online Download

Advantages And Disadvantages Of Drawing A Question Carrie L Lewis Artist

Lecture 17 Drawing Practice And Force Ppt Video Online Download

0 comments

Post a Comment